What is the importance of remote IO modules? What are the functions?

The development of technology is advancing rapidly, and the tide of the times is surging forward. Electronic products have become an indispensable part of life and work. Many electronic devices work together to generate some signal sources. In order to better transmit and collect signals, industrial control products such as remote IO modules, signal transmitters, and signal acquisition modules have been developed. So, what is the importance of remote IO modules?

Many electronic devices work together to generate some signal sources. In order to better transmit and collect signals, industrial control products such as remote IO modules, signal transmitters, and signal acquisition modules have been developed. So, what is the importance of remote IO modules?

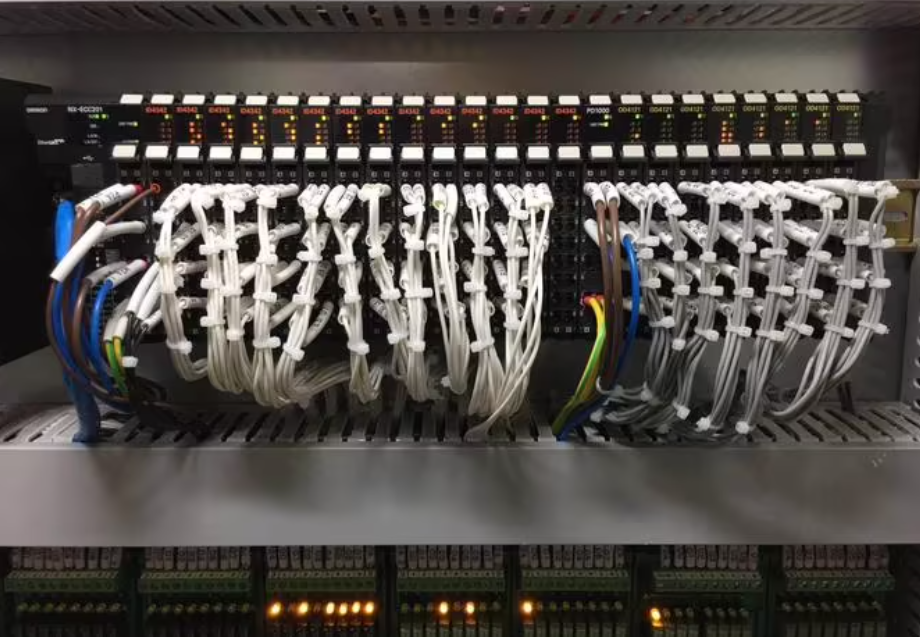

Previously, when laying ready-made panel and cabinet circuits, people had to connect them one by one, which greatly increased the cost and construction time of cables. If the distance is far, they will face issues such as voltage decay. With the remote IO module, this problem has been effectively solved.

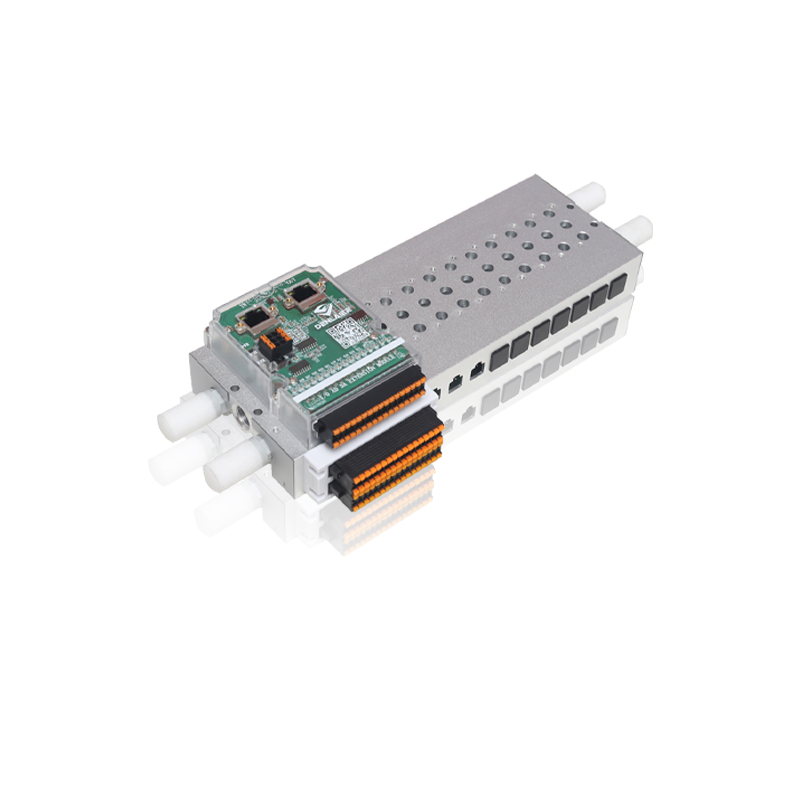

In short, remote I/O is a data acquisition/transmission module with communication functions, which does not have control and adjustment functions. Simply send on-site data information to the control research center (such as PLC), or receive data from the control management center to control construction site equipment. There are many communication methods, and each manufacturer has their own standards, such as free port communication, PROFIBUS, MODBUS, etc.

If your cabinet is 200 meters away from the site and you do not choose remote IO or Ethernet protocol, then each power cord needs to be laid out for 200 meters. Then, remote laying out IO installs modules on site, reducing the walking line of Ethernet bus, which can save you a lot of cable costs and reduce the complexity of construction.

Generally speaking, in order to save on cable procurement and construction, some IOs are sometimes set up in areas where on-site equipment is concentrated and far from central control, and then the optical fibers are connected back to the central control room. Sometimes, the logical reason for 'remote' is mainly because the allowed total number of 'local IO' cannot meet the actual needs, and it is necessary to connect to the 'remote IO template', mainly depending on the actual situation.

In addition, the cabinet room is usually located on site of the equipment. However, the control room has implemented some control signals, such as emergency stops, bypasses, etc. Therefore, it is necessary to choose remote control signal IO to send these signals to the cabinet control system.

Follow WeChat

Follow WeChat Official account

Official account